HLS Hydraulic Link Clamp - Hydraulic lever clamp

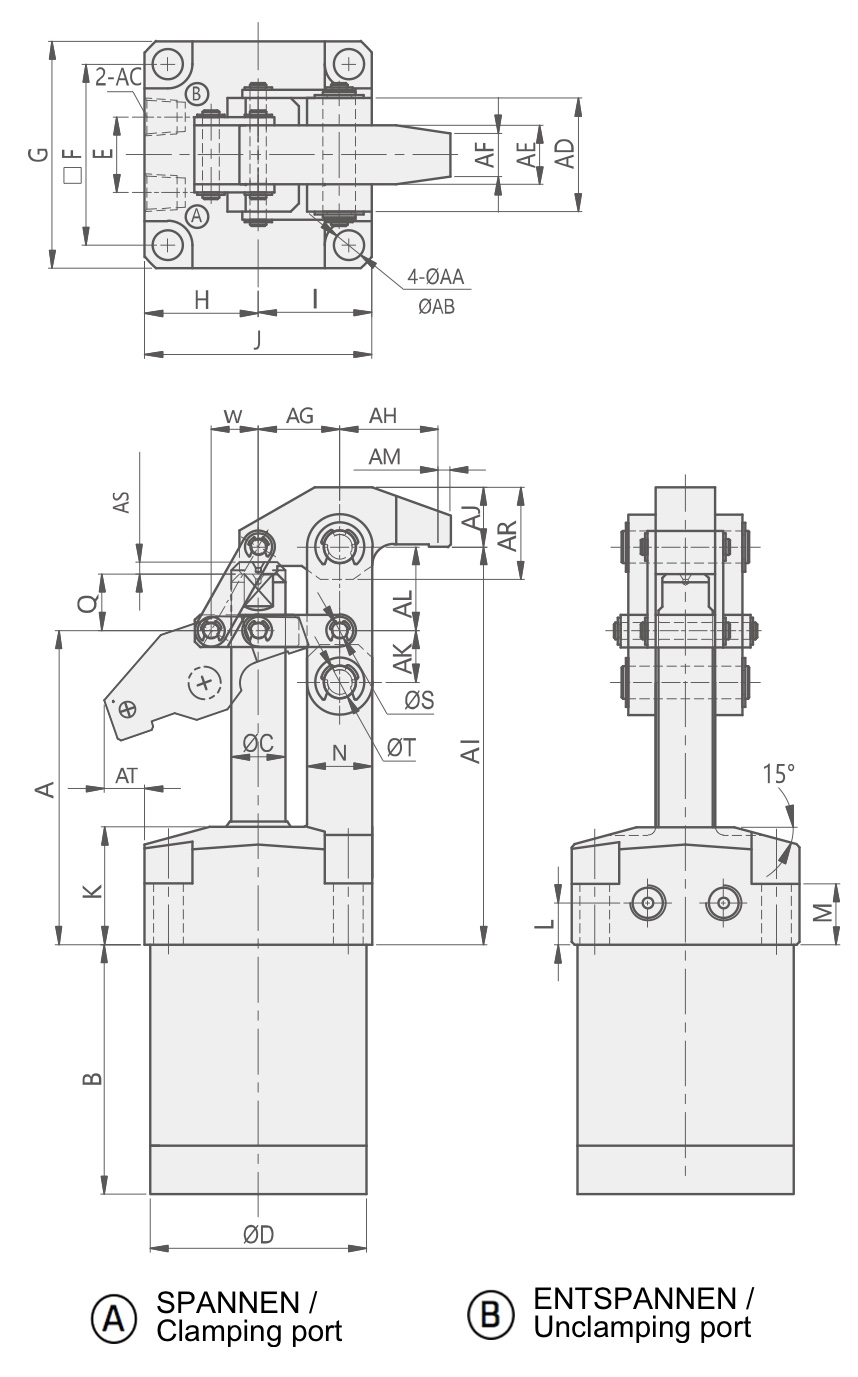

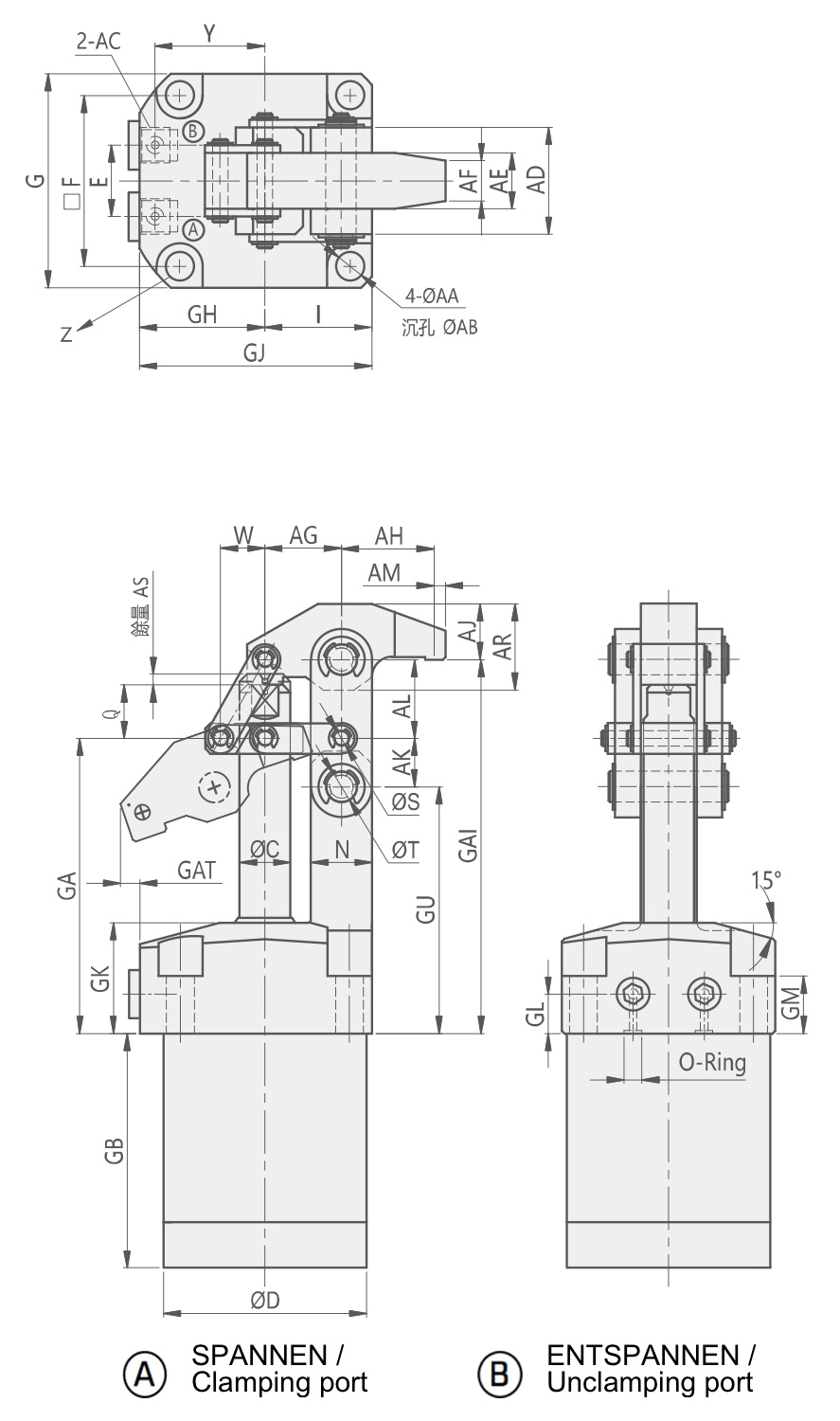

Hydraulic Link Clamp - Hydraulic Cylinder :

- Designed for high clamping forces with low operating pressure

- Particularly designed to reduce the interference with loading and unloading operation.

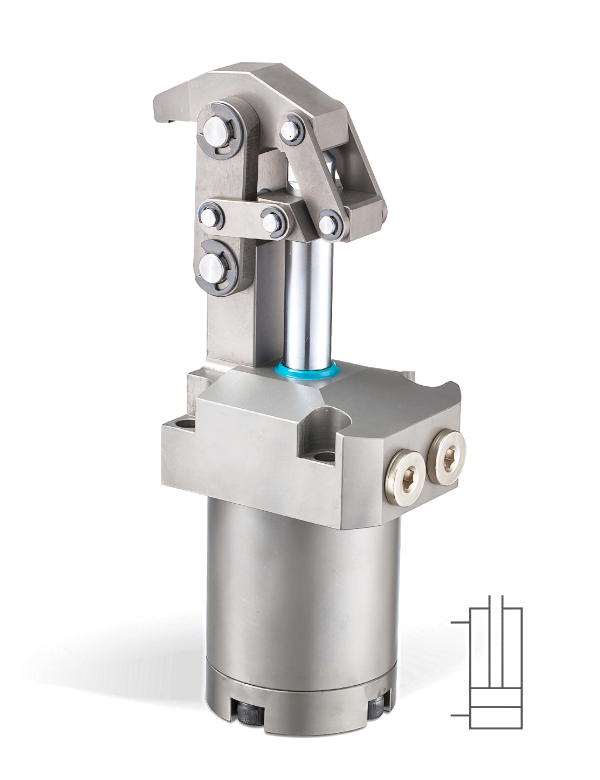

- Material cylinder body and clamping arm : C45 steel, nitrated

- Material piston rod : high alloy steel, hardened and tempered

- Manifold piping and G port piping are optional available.

- Clamping forces 2,9kN up to 11,36kN (4 cylinder sizes)

- Complete with lever mechanism and clamping arm

- High-quality seals resistant to chlorine-based cutting fluid and prevent infiltration of cutting chips and dust.

- Min. operating pressure : 10bar

- Max. operating pressure : 70bar

- Range of Temperature : -10 ~ +70°C

- Customized versions are available on request.

➝ CAD-files and prices on Request !

Example ordering code:

HLS - 32 G

Series – Cylinder inside diameter – Port type

| ① | SERIES | HLS | |

| ② | Cylinder inside diameter |

25 :Ø25 mm

32 :Ø32 mm 40 :Ø40 mm

50 :Ø50 mm |

|

| ③ | Port type | Blank: Standard Line type (tube type) G: Manifold type (O-ring/Gasket type) |

| Model | Clamping force at 70 bar | Clamping stroke | Total stroke | Oil capacity Clamp | Oil capacity Unclamp | eff. piston area clamp | eff. piston area unclamp | CAD |

|---|---|---|---|---|---|---|---|---|

| [kN] | [mm] | [mm] | [cm³] | [cm³] | [cm²] | [cm²] | ||

| HLS-25 | 2,9 | 31,5 | 34 | 16,69 | 11,46 | 3,37 | 4,91 | |

| HLS-32 | 4,41 | 35,5 | 38 | 30,55 | 25,05 | 6,6 | 8,04 | |

| HLS-40 | 7,09 | 41 | 44 | 55,26 | 46,46 | 10,56 | 12,56 | |

| HLS-50 | 11,36 | 47 | 50 | 98,15 | 82,45 | 16,49 | 19,63 |